Using Scales for Fertilizer & Micronutrient Solutions

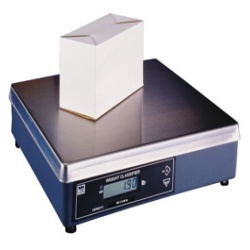

Micronutrients for CropsIn agriculture, precision and efficiency are very important. Recently a company specializing in liquid and granular fertilizer handling equipment, and developed a unique application system to optimize crop growth and soil conditions. At the heart of this operation lies the Rice Lake 920i FlexWeigh filler/batching systems and BenchMark bench scale or Summit 3000… Read More »