Today we attempt to answer the question that many a purchasing agent or warehouse manager has surely pondered….

Should I buy a 4×4 or a 5×5 floor scale?

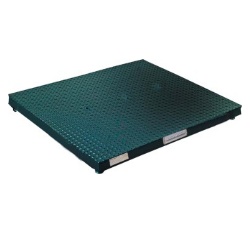

Have you ever gone looking for a simple floor scale to weigh pallets? Only to be confused by whether you need a 5×5 or a 4×4 model. You’re not alone. There are many before you that have had the same question or something similar. It may have been about low price floor scales online or possibly about pallet scale calibration or scale troubleshooting. These are all platform scale subjects we have covered many times on this website. But getting back to the main point, should you buy a platform scale that’s 48″ x 48″ or 60″ x 60″?

This article is meant to provide a brief comparison while giving you confidence to make the correct decision when shopping for a standard industrial floor scale. While the 4×4 floor scale is actually the most common scale purchased, the 5×5 has a slight advantage of being able to, accommodate the full length of a pallet jack without fear of rolling off the back of the scale.

Which Scale is Better for me? 5×5 or 4×4

As we say, with truck scales, trucks aren’t getting any shorter, and pallets, by the same token, aren’t getting any smaller. So, if you have the room in your warehouse, then you should strongly consider the 5×5 pallet scale. With the exception of the additional surface area and the additional cost of the 5×5 floor scale. These two scales are identical from most manufacturers. One exception would be since the 4×4 floor scales are often mass produced, Manufacturers may try to use a thinner deck plate that is more widely available. This naturally makes the mass produced scale less durable and exposed to more deflection of the weighbridge and that could possibly lead to more inconsistent weights and possibly even a shorter lifespan. Although they are less common, another consideration that might make sense for you would be a 5×4 scale.

4 Foot Long Scale Ramp is Recommended for a Pallet Jack

And don’t forget if you’re looking to roll a pallet jack onto the scale, then you will need to have enough space for a ramp for pallet jack use. Most scale manufacturers recommend a four foot long ramp. So you will want to make sure you have the floor space for a 5×5 scale and a 5×4 ramp as well. You might also want to check out our entry about scale with a ramp vs. in floor scale.

We hope this entry has helped you out. If you need assistance or you’re looking to get some product and price information, please fill out our RFQ form on our site or you can call us at (919) 776-7737.