Using vehicle scales at a rail freight logistics facility is important for a variety of reasons, including cost savings, safety, and efficiency. Below, we will explore these reasons in more detail.

Rail service has an amazing history of fueling this country’s overall economic growth by moving freight across the country. But if you think about it, rail service isn’t the most popular choice of travel in most folks minds when it comes to their logistics and supply chain optimization strategy.

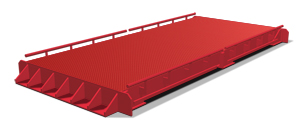

In addition to railroad track scales, rail logistics service solutions can often benefit from having a 70’x11′ truck scale at their facility. Or perhaps a larger platform such as 80′ x 11′ or even 90′ x 11′ would work better?

Intermodal Travel for Containers or Trailers

Intermodal freight focuses on the best way to send long haul shipments domestically, utilizing both truck and rail to move containers & the traditional 53′ domestic containers that you’ve surely seen on the highways. Basically, in a lot of people’s minds, “intermodal” is the better way to ship, both economically and environmentally, for truckload shipments of 700 miles or more. There are two types of domestic intermodal shipping in container-on-flatcar (COFC) and trailer-on-flatcar (TOFC).

Using truck scales at a rail freight logistics facility can help to save money. Accurate measurement of cargo using vehicle scales allows facilities to optimize the use of railcars and ensure that they are not overloading or underloading them. Overloading railcars can lead to additional costs, such as the need for additional railcars or the need to pay overweight fines. On the other hand, underloading railcars can lead to wasted space and lost revenue. By using scales to accurately measure the weight of cargo, facilities can optimize the use of their railcars and reduce costs.

In addition to cost savings, using scales at a rail freight logistics facility can also help to improve safety. Accurate measurement of cargo using truck scales can help to reduce the risk of accidents or injuries caused by handling heavy or unbalanced loads. This can help to create a safer work environment for employees and protect the overall safety of the facility.

Using Truck Scales for Rail Logistics Services

Using 70 foot long scales at a rail freight logistics facility can help to improve efficiency and productivity. Accurate measurement of cargo using scales allows facilities to more accurately plan and execute the loading and unloading of railcars, which can help to reduce the time and labor required to process each shipment. This can help to increase the overall efficiency and productivity of the facility, leading to increased profitability.

The use of 80 foot long truck scales at a rail freight logistics facility is important for cost savings, safety, and efficiency. By accurately measuring and weighing cargo, facilities can optimize the use of their railcars, reduce the risk of accidents or injuries, and improve the efficiency and productivity of their operations. It is critical for rail freight logistics facilities to use and maintain weight scales in their daily operations.