Let’s say you are now the leader of the warehouse crew or perhaps the manager of the manufacturing branch that you work at. And let’s say that the past leaders have been a little slow to change with the times when it comes to adding new technology to the overall process. Of course, that includes your weighing process as well. So if you’re at that point, you may ask, what scales do I need for my warehouse? Well let’s take a look at some weighing equipment ideas that will help your business.

Weighing Incoming and Outgoing Pallets

Many businesses have pallets that need to be weighed. These could be shipments you’re bringing in or shipments you’re sending to your customers. Or, perhaps you’re weighing incoming and outgoing shipments. No matter what, you really need to add a scale to this process. Guessing pallet weights can be costly!

Many folks choose to add a stationary scale with a ramp to their warehouse floor. Sometimes they even add several of these platform scales throughout the building. These scales are typically either 4×4 or 5×5 size scales that will weigh pallets up to 10,000 pounds.

These floor scales are very popular and work very well. Please note if you buy one of these you will want to work with a reputable scale company like Central Carolina Scale to make sure you choose a quality pallet scale that matches your work flow and durability needs. Also, don’t forget if you buy a floor scale with a ramp or two, that is going to take up a lot of warehouse floor space.

Another option that some companies do is purchase a pallet jack scale. In this case you bring the scale to the pallet. This can be more efficient in some cases since you’re not driving around trying to find a platform scale or waiting in line at the scale. You have to be careful with this group of scales since there are some very cheaply made imported pallet trucks that you want to stay away from. Good idea to stick with reputable brands of pallet jack scales like CAS and Rice Lake.

Companies also will sometimes choose a forklift scale. These are weighing scales that are installed on the front of your existing forklift. We have multiple brands of these scales available and they often need to be installed by your local scale company for best results. When these get added to your forklift, the capacity of the forklift is often slightly decreased. We also have Ravas iForks which are basically fork attachments with scales that you can easily add to your own forklift in a half hour or less!

Counting Parts for Inventory

If you have any parts on your shelf like nuts, bolts, screws, washers, or basically anything that you have lots of that weighs the same, you can count them super fast with the aid of a parts counting scale. We have lots of different varieties of counting scales and once again you will want to contact the sales department to make sure you get the right scale for what you’re looking to do. We have parts counters that can do everything from count out very tiny little rubber o-rings or resistors to printing out labels that show how many parts are in a box.

Time to Ship Out Some Boxes

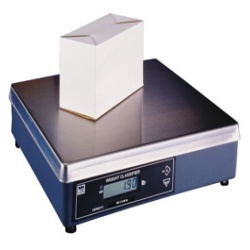

If you’ve done any shipping lately then you know how important it is to have accurate shipping scales for shipping out your parcels. It doesn’t matter if it’s UPS, FedEx, or USPS accurate weights matter and if you don’t enter the correct weights when you’re shipping out boxes, the carriers will add fees and penalties to your billing statement.

And another factor to consider for your shipping stations is figuring out a way to come up with box dimensions. The shipping carriers like UPS are starting to measure the dimensions of boxes and that is something you must start doing with all your shipments. And, it’s not just box dims being examined, dimensions are also being measured for your LTL shipments with carriers like Old Dominion, R&L Carriers, XPO Logistics, T-Force and more.

When it comes to measuring boxes and pallets, you can do it by hand, which we’ve discussed before. However, that can take some time. And, if you’re only shipping out a handful of boxes or pallets everyday, it might work out ok. Another thing to consider is that you are usually going to need to manually enter the box dimensions into your shipping software…. for each box or pallet that you ship. And, this could lead to some errors just by someone typing the wrong number. (Don’t worry, the freight carrier will let you know if your measurement is wrong on next months billing statement)

The good news is that if you’re shipping out a decent number of boxes or pallets on a daily basis, then you really need to take a look at our dimensional weighing and measuring devices that we offer. You can add a box or pallet measuring device right above your scale!

Speed up your weighing and measuring process with fast results and some hard data that you can show the freight companies if there is ever a dispute about weight or dims. Be sure to contact our sales department about these time saving items.

Speed up your weighing and measuring process with fast results and some hard data that you can show the freight companies if there is ever a dispute about weight or dims. Be sure to contact our sales department about these time saving items.

Miscellaneous Tasks and Everyday Activities in the Warehouse

We’ve covered many of the typical tasks that you might run into in a warehouse or manufacturing setting. But the truth is there are many other situations where a scale might work for your needs. And believe it or not, there are many, many different types of scales!

Maybe you need a drum scale to weigh barrels or drums? Or perhaps you need to fill a drum to a certain amount and have the scale alert you once it gets to a certain weight. Maybe you need a simple bench scale or counter top scale for weighing basic things around the office from time to time. Maybe you’re putting kits together of small parts and you need to checkweigh these kits to make sure they all weigh between 1.6 and 1.7 pounds? Of course there could be applications where you need to weigh inbound or outbound trucks too.

I hope this entry has helped you better understand what scales you need for your warehouse. Several of the scales that I mentioned are industry standard items that virtually everybody uses, while other items like dim measuring is just starting to become important. Be sure to contact our sales department to determine what your weighing needs are. You can complete the RFQ form linked above or call (919) 776-7737.