YOUR TROUBLE SHOOTING GUIDE FOR INDUSTRIAL FLOOR SCALES

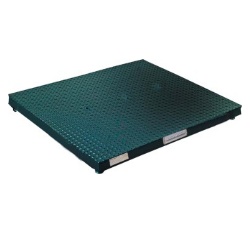

Pallet scales typically take a lot of wear and tear every single day. Some of it is expected and some of it goes overboard. Of course floor scale users are supposed to “place” or “set” pallets on the scale platform. However, in the real world “placing” is usually somewhere between outright dropping and slamming.

Also, in addition the the shock loading many floor scales often take everyday, the scales are often utilized in harsh environments such as outdoors, recycling centers, food processing centers, etc… In fact, floor scales are often subject to high pressure washdowns, corrosive materials, overloading, hazardous areas, and much more.

That’s why it’s important to have your platform scale checked periodically on a consistent schedule. We can help you with that! Ask us about our Service Agreements that we offer.

However, even with the best scale maintenance program, weighing equipment can fail between scale inspections.

So, is there anything you can do to troubleshoot your floor scale?

Actually, there are several steps you can take. Below is a list of floor scale troubleshooting tips to make sure your industrial floor scale is working correctly. Keep in mind, if you try the list below and your pallet scale still isn’t working, you will need to contact our scale repair department by calling (919) 776-7737

HOW DO I TROUBLESHOOT A FLOOR SCALE?

PROBLEM

Any floor scale related problem

POTENTIAL CULPRIT

Anything

SOLUTION

Unplug the power from the scale for a minute and then plug the power back in after a minute or so. It seems too simple, but you’d be surprised how often this works.

PROBLEM

Floor scale not reading correctly

POTENTIAL CULPRIT

Could be something under the weighbridge, weighbridge shoved against a wall, bent foot, cut cable, etc..

SOLUTION

This may take a few minutes of your time but it might save a service call. Look for anything under the scale platform. Make sure the platform is not shoved against a wall or pit frame (learn more about floor scale with ramp vs in-ground scale). Make sure all four feet are in good shape and solidly on the ground. Make sure the homerun cable has no obvious cuts. If that doesn’t work, it’s best to call our service department.

PROBLEM

Pallet scale display either shows all “- – – -” or is constantly displaying different numbers

POTENTIAL CULPRIT

This could be a cut cable. This could also possibly be a bad load cell.

SOLUTION

Examine the cable. If you see a cut, it might be a good idea to replace the cable. If you see nothing wrong with the cable, you might try disconnecting the load cells in the junction box, one by one and see if that calms the system down. If that works, you might have a bad load cell(s). If that does nothing, you might have an indicator issue. At this point, you probably need to contact the scale service department so that our factory trained scale technicians can get to work and have you back weighing again.

FLOOR SCALE TROUBLESHOOTING ADVICE

The good news is that we stock many of the replacement scale parts that are needed for floor scale repairs. We have replacement shear beam load cells in many of the capacities you may need like 2.5k or 5k. We have summing boards that are used to connect all the load cell wires. We have digital weight indicators and we have load cell cables that run from the digital weight display down to the platform scale. Call our service department (919) 776-7737 to get booked on our schedule.