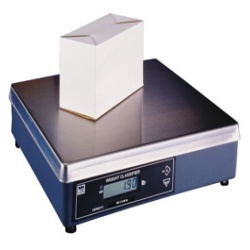

Industrial Scale Service Cost Guide & Recommendations

There is no doubt about it, an accurate weight scale is an essential device for just about any company. And it’s extremely important to any company who directly uses scales in their daily process. I’m sure you’ve probably seen the online calculators that compute scale accuracy versus dollars lost due to inaccurate scales. If you… Read More »