Use up and down arrows to select available result. Press enter to go to selected search result. Touch devices users can use touch and swipe gestures.

We sell, repair, calibrate & rent scales

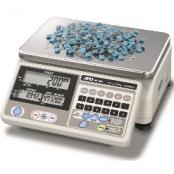

Portable Counting Scales can also be described as an easy way to take your digital counting scale with you around the warehouse. Built-in rechargeable battery packs can sometimes provide up to 200 hours of continuous use and scales not only monitors the battery life, but also recharges the battery while the scale is in operation insuring no unexpected "down time". Counting scales for sale from Avery Weigh-Tronix and Salter Brecknell, come with easy to read digital displays are rugged, dependable, and ideal for accurate inventory management in warehouses and work great with parts with small precision unit weights.

When accuracy counts, you can count on us at Central Carolina Scale to provide you with a complete line of electronic scales that you can take with you around the warehouse. Portable, efficient and accurate, our portable scales are ideal for anywhere an exact count is required. If you need assistance, contact us (919) 776-7737 and we can get a price to you for whichever item you are interested in below. If you're looking for something with more bells & whistles, you'll need to see our programmable lineup. Something more robust? See our industrial counting scales. We can work with you to find the best scale for the money. Need something to safely pick up your product, try one of our scoops.

When you invest your resources into an electronic scale with portability that includes a parts count feature, you actually help your business be more efficient and profitable. The reason is simple. If you try to count parts out by hand, you inevitably make mistakes, which leads to inventory errors and incorrect data on your important financial statements. When you add one of these machines above to your inventory process, you minimize errors and increase productivity since an employee is able to quickly confirm all the inventory. Check out the Buying Guide for more assistance.

The smallest item a scale can count is dependent on the minimum piece weight. Calculating the minimum piece weight can be done in different ways and can be quite complicated...

But, a very simple and effective way to estimate this is to multiply the manufacturer’s recommended readability by five. This will give you a close estimate of the average piece weight the scale should weigh within.

As an example, to estimate the average minimum piece weight of a typical 60 pound capacity counting scale with an analog cell, displayed resolution of 30,000 divisions and stable readability of 60,000 divisions (0.001 lb.), you would use the following: 0.001 x 5 = 0.005 lb. Now compare that to a 70 pound capacity ZK830 scale from Avery Weigh-Tronix with displayed resolution of 100,000 divisions and stable readability of 3,500,000 divisions (0.00002 lb.), the estimated average minimum piece weight is 0.00002 x 5 = 0.0001 lb. This is the smallest recommended item each of these scales can count within the accuracy bounds selected.

While calculating the average minimum piece weight is useful to customers, on highly accurate counting scales with high internal resolution such as the ZK840, the piece weight can be calculated using the minimum sample size that will always guarantee the accuracy the customer has set within the scale.

On the ZK Counting Scales, the minimum sample weight can be easily calculated by using 0.01% of the scale’s full base capacity for dribble counting or 0.02% of the scale’s full base capacity for bulk sampling. This means that a on a 70 lb. scale, the scale can accurately calculate a pieces weigh with 99.75% accuracy by using a minimum sample weight over 0.007 lb. This minimum sample weight could come from a sample size of 5, 10, 50 or more pieces.